How to Connect a 3 Phase Energy Meter: Step-by-Step Guide

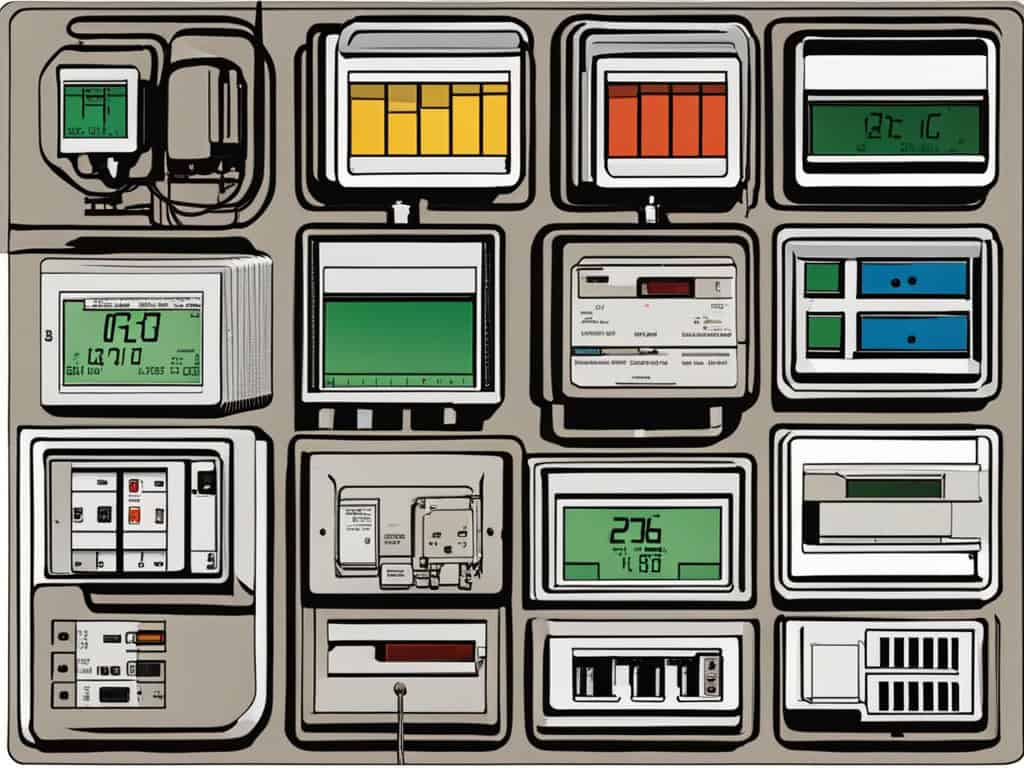

How to Connect a 3 Phase Energy Meter: A Step-by-Step Guide for Properly Installing and Wiring a Three-Phase Power Meter for Commercial or Industrial Use.

Did you know three-phase energy meters are very important in India? They are key for many businesses and factories. Demand for these meters is increasing. It’s expected to grow by over 20% in the following three years. This growth is due to the need for better energy monitoring and management.

If you’re a business owner, a manager, or an electrician, knowing how to connect a three-phase energy meter is key. It makes sure you get the right information on energy use. This helps in making your energy use more efficient. We will guide you through the entire process. From picking the right spot to checking and calibrating the meter.

Key Takeaways

- Three-phase energy meters are crucial for accurate energy measurement in commercial and industrial settings.

- The installation process involves selecting the right location, installing current transformers (CTs) and potential transformers (PTs), connecting the energy meter, and verifying the connections.

- Proper sizing and selection of CTs and burden resistors are essential for accurate current measurements.

- Calibrating the current reading and monitoring energy consumption are important steps for effective energy management.

- Consulting with the electricity provider and a licensed electrician is recommended before undertaking any meter installation or modification.

Understanding Three-Phase Meter Connections

In big places like companies and factories, using three-phase meter connections is key. They help measure how much electrical energy is used. These systems have three phases (A, B, and C) plus a neutral part. With the right connections, businesses can watch their energy use closely.

Importance of Three-Phase Meter Connections

Three-phase meter connections are vital in big settings to measure energy right. They give a broad look at how power is used, helping businesses cut costs. By setting up meters correctly, they can spot where they use too much energy.

Key Components of Three-Phase Meter Connections

A three-phase energy meter, CTs, PTs, and the metering panel are important parts. The energy meter tracks power use in detail. CTs and PTs lower the high current and voltage to safe levels. The metering panel keeps everything secure and connected.

how to connect 3 phase energy meter

Step 1: Selecting a Suitable Location

To set up a three-phase energy meter, choose the right spot first. It should be close to the main power supply for easy access. Also, keep it indoors to protect it from the weather and maintain its accuracy.

Step 2: Installing Current Transformers (CTs)

Next, you need to put current transformers (CTs) on each phase. Make sure these CTs are perfectly in line with the wires and are tightly connected. This is key for the meter to measure current correctly.

Step 3: Installing Potential Transformers (PTs)

You then connect potential transformers (PTs) to each phase, paying attention to the right polarity. It’s also important to ground the PTs well. Doing this prevents damage from voltage surges and supports accurate voltage readings.

Step 4: Connecting the Energy Meter

Mount the three-phase energy meter securely in the panel. Connect the CTs and PTs to the meter’s terminals according to the manual. Ensure all the wires are properly connected and fastened tight.

Step 5: Verifying Connections and Performing Testing

Check all connections to make sure they’re correct and in good shape before turning on the system. Once everything’s verified, close the panel. Now, it’s time to start the system and test it to guarantee the measurements are precise.

Choosing the Right Components

Picking the right parts for your three-phase energy meter is key. It helps measure energy well and boosts the system’s performance. Here are the main things to think about when choosing components.

Selecting the Appropriate Current Transformer (CT)

Choosing the right current transformer (CT) is vital for accurate energy readings. The CT’s size should match the maximum continuous power the system uses over the supply voltage, often 110V or 220V. For best results, the turns ratio of the CT should be between 500:1 and 5000:1.

Sizing the Burden Resistor

The burden resistor changes the CT’s current into a voltage the energy meter can use. To find its size, divide the highest expected current by the CT’s turns ratio. Then, figure out the resistance needed with R = V/I, and pick the nearest standard value resistor.

Determining Capacitor and Dividing Resistor Values

For ordinary home needs, a 10μF capacitor works well. The dividing resistors, which help set the 2.5V reference voltage for the Arduino, should have the same value. For example, you can use two 100kΩ resistors.

Fenice Energy is your go-to for green power solutions, like solar and EV charging. We have over 20 years of experience, helping businesses manage their energy better.

Calibrating and Operating the Three-Phase Energy Meter

Calibrating the Current Reading

To calibrate the current reading, use a calibrated load. This could be incandescent light bulbs. By comparing the meter’s display with the actual load, you adjust scaling factors. This ensures current readings are correct.

Monitoring Energy Consumption

After calibration, you can monitor energy consumption. The meter shows current, power, max power, and kilowatt-hours for each phase. This allows for good energy monitoring and management.

| Metric | Value |

|---|---|

| Current | 15.7 A |

| Power | 3.4 kW |

| Maximum Power | 5.2 kW |

| Kilowatt-hours Consumed | 987 kWh |

Fenice Energy provides clean energy solutions. Their services include solar, backups, and EV charging. With over 20 years of experience, they help businesses manage their energy.

Conclusion

The right setup and connection of a three-phase energy meter matter a lot for measuring energy well. This is very important for keeping track of how much energy is used in places like business sites. Following the steps to set up and understand the parts is key. It helps businesses use the meter correctly to better watch their energy use.

Fenice Energy is a go-to for businesses wanting to manage energy better. They offer clean energy solutions in India like solar power and more. With over 20 years in the field, they help companies lower energy costs and be kinder to the planet.

Getting a good three-phase energy meter and working with Fenice Energy can do wonders. It allows businesses to measure energy well and manage it smartly. They get to choose the best clean energy choices. This knowledge helps them cut down on harmful emissions and succeed in a new world of energy solutions.

FAQ

What are the key steps involved in installing a three-phase energy meter?

First, pick a good place for the meter. Next, put current transformers (CTs) on each phase. Then, add potential transformers (PTs) to lower the voltage. After that, connect the meter. Finally, check all connections and do tests.

Why are three-phase meter connections crucial in commercial and industrial settings?

In places like stores or factories, it’s key to get energy use just right. Three-phase meters do that by using three phases and a neutral. This setup helps businesses keep a close eye on their energy use.

What are the key components of a three-phase meter connection?

The main parts are the meter itself, current transformers (CTs), and potential transformers (PTs). There are also the metering panel for housing. The meter measures power use and checks the voltage, current, and power factor. CTs and PTs adjust high currents and voltages to safer levels for the meter to read. The panel holds everything together.

How do you size the current transformer (CT) for a three-phase energy meter?

Pick the right size CT for precise energy measuring. Consider the highest power it will measure, divided by the voltage needed. A turns ratio from 500:1 to 5000:1 works best.

How do you calibrate the current reading of a three-phase energy meter?

Use a known load, like special light bulbs, to calibrate the meter. Compare the meter’s reading to the actual load. Then adjust the settings until it shows the right current.